Probably the last thing you think about when entering into a hardscaping project as a homeowner is the base installed underneath the stones or pavers. And why should you - you're not a mason. Leave it to the professionals.

That sounds good in theory, but, like everything, the "science" of hardscape bases has evolved over time. Materials that masons had available to use a generation ago have changed. The amount of precipitation we receive as rain rather than snow during the winter has changed. The dawn of the "Unilock Paver Age" has come and concrete pavers are now used quite widely in the industry. Note that they are properly called Concrete Modular Units or interlocking concrete pavers There are a lot of different interlocking concrete paver manufacturers besides Unilock out there now, with varying degrees of product quality and different styles.

The make-or-break principle behind every hardscaping project, whether CMUs, natural stone or porcelain pavers, is to create a stable base. Without that the stones or pavers can shift with time, undergo frost heave, or crack. The hardscape can't stay properly pitched to shed surface water flow if it shifts, and puddles can form that degrade the hardscape as well as presenting safety hazards. There are now standards for what is required in different climates and for different soil types - those standards are specified in construction documents and are supposed to be followed by the contractor. I think its still important for homeowners to have a basic understanding of materials and techniques involved.

The information below refers to the base used for interlocking concrete pavers but the same principles apply to natural stone. Porcelain pavers have their own set of specialized requirements so what's written here doesn't apply to porcelain. (The choice of hardscape material to use for any given project is a topic for another day.)

For many years, experts have recommended the use a compacted base conforming to ASTM D 2940. The terminology for this product — a mix of fines and angular stone up to +/- ¾ inches in size — varies across regions and ranges from “Item 4’”to “Crusher Run”. But as permeable pavers became more available and widely used, the industry had to come up with a different base material, because fines can't be present in permeable paver installations. Fines clog up the spaces between the gravel under permeable pavers, which is meant to be a reservoir to hold stormwater to let it percolate over time into the underlying soil. Base material without fines is known as “clean gravel”, the basis of the terminology open-graded - because the spaces between gravel are open rather than filled with fines.

Continued experience and further research has shown that the use of open-graded base materials is applicable to more than just true permeable paver installations. In fact, most manufacturers now recommend using open-graded bases for all types of concrete pavers, and a number of “how-to” and “why” videos are available on line.

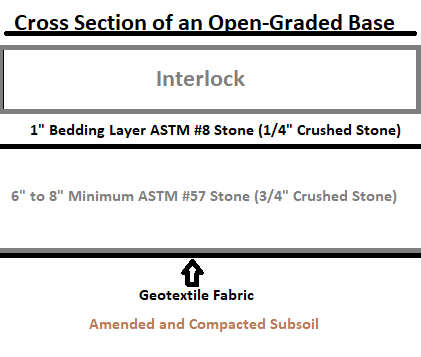

The open-graded base is installed using two different types of aggregates:

1. ASTM #57

This is ¾ inch open-graded crushed rock with no fines that is used for a recommended minimum of 6 to 8 inches after installing a geotextile fabric to separate the subsoil from your base. It has a high compaction rate, so more can be laid in lifts before compaction.

2. ASTM #8

This is a ⅜ inch or sometimes found as ¼ inch open-graded crushed rock with no fines that is used up to 1 inch deep as the final bedding layer for leveling (a substitute for the more traditionally-used concrete sand). It has a near 99% compaction rate and is incredibly easy to work with as a leveling stone.

Both of these stones should be angular crushed. Be sure to verify this with your supplier before ordering as this is crucial to the compaction of your base material - stone without edges does not compact well!

Spec diagram for an open-graded base used with regular interlocking concrete pavers. If the installation was for permeable pavers, there would be an additional reservoir at least 12 inches deep of larger diameter clean stone functioning as a reservoir to allow stormwater to percolate over time.

ASTM #57

ASTM #8

It's time to say goodbye to fines and use clean stone for all hardscaping projects.

Why?

An Item 4-type base with fines does not provide the best combination of the two most important aspects of the paver base: proper drainage and the load-bearing capacity necessary for appropriate traffic. Using a ¾ inch clean gravel layer and an angular chip stone bedding layer yields much better drainage performance, as well as providing equally sufficient load-bearing capacity to the Item 4-based method.

Other benefits include:

• The bedding can (carefully) be walked on without creating substantial footprints

• It can be used for all product sizes

• It is ideal for raised patios and steps because this system eliminates sand washout

• It is more difficult for weeds to root and thrive in cleaN stone

• There is no room for insects to nest under the pavers

• The materials are workable in essentially any climate, as well as inclement weather

Additional advantages

An Item #4 and sand setting base holds water and creates imperfections in the base. An open-graded base, on the other hand, is free draining, therefore any water that does permeate through won’t sit just below the surface in a water-logged Item #4 base. That, in turn, prevents expansion/contraction as part of the freeze/thaw cycle that could otherwise shift pavers or stones. Open-graded is much more appropriate for Northeastern weather conditions.

The clean stone in an open-graded base actually makes compaction much easier. Achieving the proper compaction requires much less time using compacting equipment. (I’m not sure I fully understand why this is yet, but I’ll read more.) Using an angular chip stone bedding layer, as opposed to sand, can eliminate residual settlement due to improper compaction.

One important aspect of the open-graded base system that cannot be overlooked is the geotextile fabric.

Fabric is completely necessary in any open-graded base installation to prevent the spaces between the clean aggregates from getting clogged with soil migrating up from underneath. Separating the underlying soil from the base is crucial.

Make sure that the fabric extends up the sides of your installation and wraps up and onto the top 6 inches that extends past the edge of your interlock installation where the edge restraint will be installed. This prevents any organic material from the top and sides to filter down into your project.

This is an example of the type of geo grid fabric that is used with open-base hardscape installation.

A commonly-asked question is about migration of the ASTM #8 stone into the voids of the underlying ASTM #57 stone. This does not occur, as the voids in ASTM#57 are not as large as 3/8″ or 1/4″ chips that are being laid on top of it.

For Contractors: Using an open-graded base will save you time and money, and as a hardscaper that is all you ever want.

• EASE OF INSTALLATION

With such a high compaction rate of the two open-graded aggregates, installation of the base and leveling layer are easier. You can lay more in your lifts before compaction, which in a patio or walkway will save you one or two lifts depending on how deep you install your base.

• WORKABLE IN ANY WEATHER CONDITION

If it rains and you are installing a traditional base, you may be out of luck. Your fines will wash out or your project will become a mess quickly. With the open-graded aggregates, you can work in any weather condition. Yes, you can work in the rain without fear that your bedding layer will wash away or become a mess.

• WASHOUT

In a traditional base project with fines and sand as a bedding layer, there is a certain amount of washout that occurs and is inevitable. Especially in raised patio installations, there will definitely be washout occurring through the retaining wall of your raised patio that can lead to sinking. Open-graded aggregates are too large to wash out.

• INSECTS AND WEEDS

Insects love the fines in a traditional base installation. However, in an open-graded base system they are less likely to be burrowing through it as the stones are too large for them. In addition, weeds are less likely to establish roots in these aggregates and are much easier to pull out if they do.

• FEWER CALLBACKS

With all of these advantages over a traditional base, you will have fewer callbacks. That means fewer headaches, less wasted time, and happier customers.